Concepts and devices in the field of Pulsed-Power technology

For different innovative fields of application as for example processing of plant tissue there is a need for pulsed-power generators and loads tailored to fit to the specific application.

Applications:

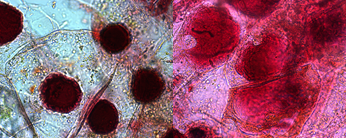

For the electroporation of plant tissue pulses with pulse lengths in the micro-second range are applied to the material by means of a set of electrodes. Pores are formed in the cell membranes enabling an easy extraction of valuable substances from the cells. The required field strengths depends on the size of the cells. While for sugar beets with a cell diameter of approximately 50 µm a field strength in the order of Ê = 3…5 kV/cm is required, opening of smaller cells, for example algae, needs a higher field strength of several 10 kV/cm.

Conventionally, in the course of the sugar production sugar beets are thermally denaturated and, subsequently, the sugar is extracted by means of a countercurrent extraction. The leached cossettes are dried and used as animal feed. The electroporation of sugar beets enables in combination with the so called alkaline extraction energy savings of at least 20% of the primary energy of the sugar factory. These possible savings comprise lower thermal losses due to an inverted temperature profile during countercurrent extraction at a slightly lowered processing temperature and less energy consumption during the high-temperature drying process of the cossettes due to a decreased residual moisture content after pressing. Moreover, the early addition of lime milk to the cossettes causes valuable substances to attach to the cossettes increasing their value as animal feed, and the alkaline milieu guards against corrosion.

Electroporation of fruit mash enables a gentle and efficient extraction of valuable substances. Currently, investigations on grape mash are carried out. Conventionally, in the course of production of red wine for the extraction of pigments from the grape skins either an up to three weeks lasting fermentation on skins or mash heating is performed. Mash heating requires a short processing time only, but there might be a slight effect on the taste. Electroporation enables a fst cell opeing without thermal degradation of the material. During the production of white wine electroporation enables a more complete extraction of valuable substances. So electroporation enhances the aroma typical for the grape variety. Moreover, an increased content of yeast digestible nitrogen prevents atypical ageing. Due to better buffering the electroporated wine has less acidity. Due to good ectraction results electroporation may substitute the use of enzymes.

Energy-efficient drying is required to obtain BtL fuels from fresh biomass. Electroporation-assisted drying enables savings in evaporation heat due to improved pressability of the biomass. Furthermore, an improved diffusion behaviour of the electroporated material accelerates the drying process. Due to a shorter dwell time in the drying kiln, kiln losses can be reduced and the kiln size can be decreased.

Test set-ups and devices:

For energy efficient processing of a product stream electroporation chambers with a substantially homogeneous field distribution in the treatment area have been designed. The electroporation chamber for the mobile electroporation device for mash treatment KEA-WEIN has been built for a voltage application symmetric to ground potential. The ground-symmetric operation enables the advantage of less insulation distance and, hence, a more compact design of the device.

For the pulse generation with pulse lengths in the micro- and millisecond range single-stage- and multi-stage pulse generators equipped with storage capacitors are used. Semiconductor switches can be used advantageously for switching smaller pulsed power. They enable pulse repetition rates of up to several Kilohertz. For high power applications switching spark gaps are the more cost effective alternative. Research and development is done in the field of both switching technologies.

For short pulses in the nanosecond range transmission-line pulse generators with semiconductor- and spark gap switches have been developed.

For electroporation of plant cells in industrial scale, for example sugar beets, an average power of up to several 100 kW is required. Together with our co-operation partner SÜDZUCKER KIT/IHM is developing an industrial electroporation device for sugar beets with a synchronous operation of several Marx generators. In order to enable a reliable ling-term operation the generators are equipped with a wear-less over-voltage trigger device. A semiconductor pulse generator generates a trigger pulse, which is added to the charging voltage of the first stage by means of a pulse transformer replacing the charging coil between the first and the second stage and, hence, causes switching of the spark gap. By means of pre-ionisation a low jitter of the switching time can be achieved.

Among measuring pulse parameters (pulse voltage, pulse current etc.) the measurement of process parameters is important for process control. For energy efficient operation of the electroporation devices a device for a continuous on-line measurement of the degree of cell opening is currently being developed. The measurement principle is based on the evaluation of the phase angle of the complex impedance of the process material a one discrete measurement frequency. The cell membranes can be considered as capacitors causing a phase shift between voltage and current when applying an ac-voltage. Pores in the cell membranes and extracted juice act as short-circuit and cause a decrease of the phase angle with increasing degree of cell opening.

Electromagnetic compatibility plays an important role in the design and setup of pulsed-power devices. All devices are designed for trouble-free operation and long lifetime.